In the fast-evolving automotive industry, ensuring the durability and safety of electrical wiring is paramount. Modern vehicles contain thousands of feet of wiring bundled into wire harnesses that must withstand harsh environments, mechanical stress, and chemical exposure.

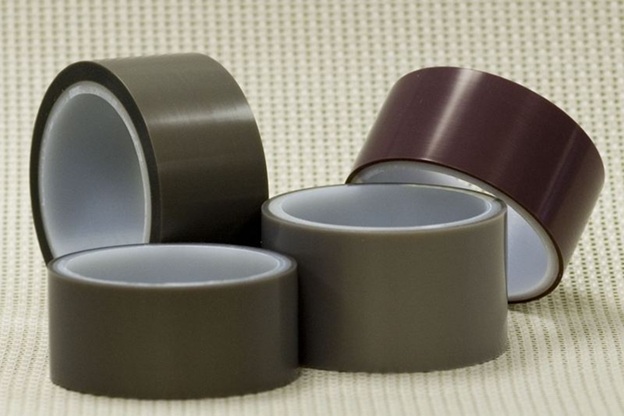

Among the materials used to protect these critical components, PTFE films have emerged as a superior solution for automotive wire harness protection.

Why Use PTFE Films for Wire Harness Protection?

- Excellent Chemical Resistance

Automotive wire harnesses are frequently exposed to oils, fuels, solvents, acids, and other chemicals. PTFE films are chemically inert, meaning they do not react or degrade when in contact with harsh substances, maintaining protection and integrity over time. - Wide Temperature Range

Vehicles operate in diverse climates and conditions — from sub-zero temperatures to extreme engine heat. PTFE films withstand continuous temperatures up to approximately 260°C (500°F) and short-term peaks even higher, ensuring wire insulation stays intact without melting, cracking, or becoming brittle. - Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. Using PTFE films reduces the risk of electrical shorts or interference in wire harnesses, critical for the reliable performance of vehicle electronics and sensors. - Low Coefficient of Friction

The slippery surface of PTFE film prevents abrasion and wear from wire movement and vibration inside the harness assembly, extending wire life and reducing maintenance needs. - Flame Retardancy

PTFE films are inherently flame-resistant and self-extinguishing, helping automotive manufacturers meet strict fire safety standards. - Flexibility and Lightweight

Despite its strength, PTFE film is thin and flexible, allowing easy application around complex harness geometries without adding significant weight or bulk.

Typical Applications of PTFE Films in Automotive Wire Harnesses

- Wire Wrapping and Taping: PTFE films are used as tapes or sleeves to bundle wires, providing a protective barrier against mechanical damage and environmental exposure.

- Shielding Against EMI/RFI: When combined with conductive layers, PTFE films help shield wires from electromagnetic and radio-frequency interference, vital for sensitive automotive electronics.

- Protecting Connector Areas: PTFE film protects connectors and terminals from moisture ingress, chemical corrosion, and abrasion.

- High-Temperature Zones: PTFE films are particularly suited for protecting wiring near engine compartments, exhaust systems, or battery packs in electric vehicles where heat resistance is critical.

Advantages Over Other Protective Materials

While polyvinyl chloride (PVC), polyethylene (PE), FEP, polyester and FEP films are common in wire harness protection, PTFE films offer unique advantages:

| Feature | PTFE Film | PVC / PE Films | Polyester Films |

| Chemical Resistance | Excellent (virtually inert) | Moderate (can degrade) | Good but less resistant |

| Max Operating Temp | Up to 260°C+ | Typically < 105°C | Up to 150°C |

| Electrical Insulation | Very high | Moderate to high | High |

| Abrasion Resistance | Excellent | Moderate | Moderate |

| Flame Retardancy | Inherent | Often requires additives | Moderate |

| Flexibility | High | Moderate | Moderate |