In the world of automation and control systems, one critical element often goes unnoticed: the I/O controller. While many people are aware of automation’s impact on our daily lives, few recognize the importance of I/O controllers in making these systems function smoothly. This blog will explore what I/O controllers are, how they operate, and why they are essential for various industries.

What Is an I/O Controller?

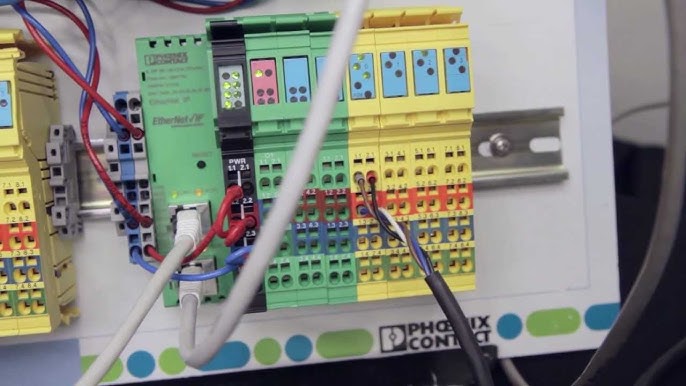

An I/O (Input/Output) controller is a device that serves as the bridge between an automation system and the physical environment. Think of it as the component that allows machines to communicate effectively with each other.

The main job of an I/O controller is to handle data from various sensors (inputs) and send commands to actuators (outputs). This can include temperature sensors in a heating system or motors that control machinery.

Components of an I/O Controller

1. Inputs and Outputs: The Connection Points

I/O controllers have several channels to receive signals from various sensors and send commands to devices. Inputs may come from:

- Digital Sensors: These sensors provide binary signals (on/off).

- Analog Sensors: These sensors give continuous signals, such as temperature or pressure readings.

On the output side, the I/O controller communicates with actuators, like motors or valves, which perform actions based on the inputs received.

2. Communication Protocols

Modern I/O controllers support various communication protocols, allowing them to connect with different devices and systems. Some common protocols include:

- Modbus

- Profibus

- Ethernet/IP

These protocols ensure data is transferred quickly and accurately, boosting the overall efficiency of the automation system.

3. Processing Power

The processing unit of an I/O controller interprets input data, executes programmed logic, and produces corresponding outputs. The processing capability varies based on the complexity of tasks the controller is designed to manage.

Why Are I/O Controllers Important?

1. Enhanced Automation

As industries move towards increased automation, I/O controllers play a significant role in optimizing operations. They streamline communication between devices, resulting in better performance and reduced downtime.

2. Flexibility and Scalability

One major advantage of I/O controllers is their ability to adapt to evolving needs. As businesses grow or change, new sensors and devices can be integrated with minimal disruption to existing systems. This flexibility allows for effective scaling of operations.

3. Improved Data Collection and Analysis

I/O controllers enable better data collection, allowing industries to gather real-time information from their processes. This data can be analyzed to optimize operations, predict maintenance needs, and enhance productivity.

4. Safety and Reliability

In industrial settings, safety is crucial. I/O controllers can be programmed with safety protocols to ensure machinery operates within safe limits. This reliability minimizes the risk of accidents, protecting both workers and equipment.

Applications of I/O Controllers

I/O controllers are used across various sectors, including:

1. Manufacturing

In manufacturing, I/O controllers help automate production lines, manage machinery, and improve quality control processes. By coordinating multiple devices, they ensure smooth and efficient production.

2. Transportation

From traffic management systems to railway signaling, I/O controllers are vital in ensuring transportation systems function correctly. They help regulate traffic flow and improve safety for all users.

3. Building Automation

In smart buildings, I/O controllers manage everything from heating, ventilation, and air conditioning (HVAC) systems to security setups. They help optimize energy use while maintaining comfort and safety for occupants.

4. Water Treatment Plants

In water treatment facilities, I/O controllers monitor and control processes. They manage water quality, flow rates, and chemical dosing, ensuring that water meets safety standards.

Choosing the Right I/O Controller

Selecting the right I/O controller for your application requires careful consideration. Here are a few factors to keep in mind:

- Compatibility: Ensure that the controller can communicate with the devices in your system.

- Processing Power: Assess the complexity of tasks the controller will handle.

- Scalability: Choose a controller that can grow with your needs.

Conclusion

As we continue to advance into an era where automation is vital to our everyday lives, understanding components like the input output controller becomes increasingly important. These essential elements of automation provide the foundation for modern systems, facilitating communication and enhancing efficiency across various industries. By embracing the capabilities of I/O controllers, businesses can improve their operations and pave the way for future innovations.

In a world that thrives on connectivity and efficiency, I/O controllers are crucial in ensuring that everything operates smoothly. Whether in manufacturing, transportation, or building automation, their role is fundamental in driving industries forward.